Power and precision for the automotive sector with ES505 spindles for Anger Machining

Watch the video

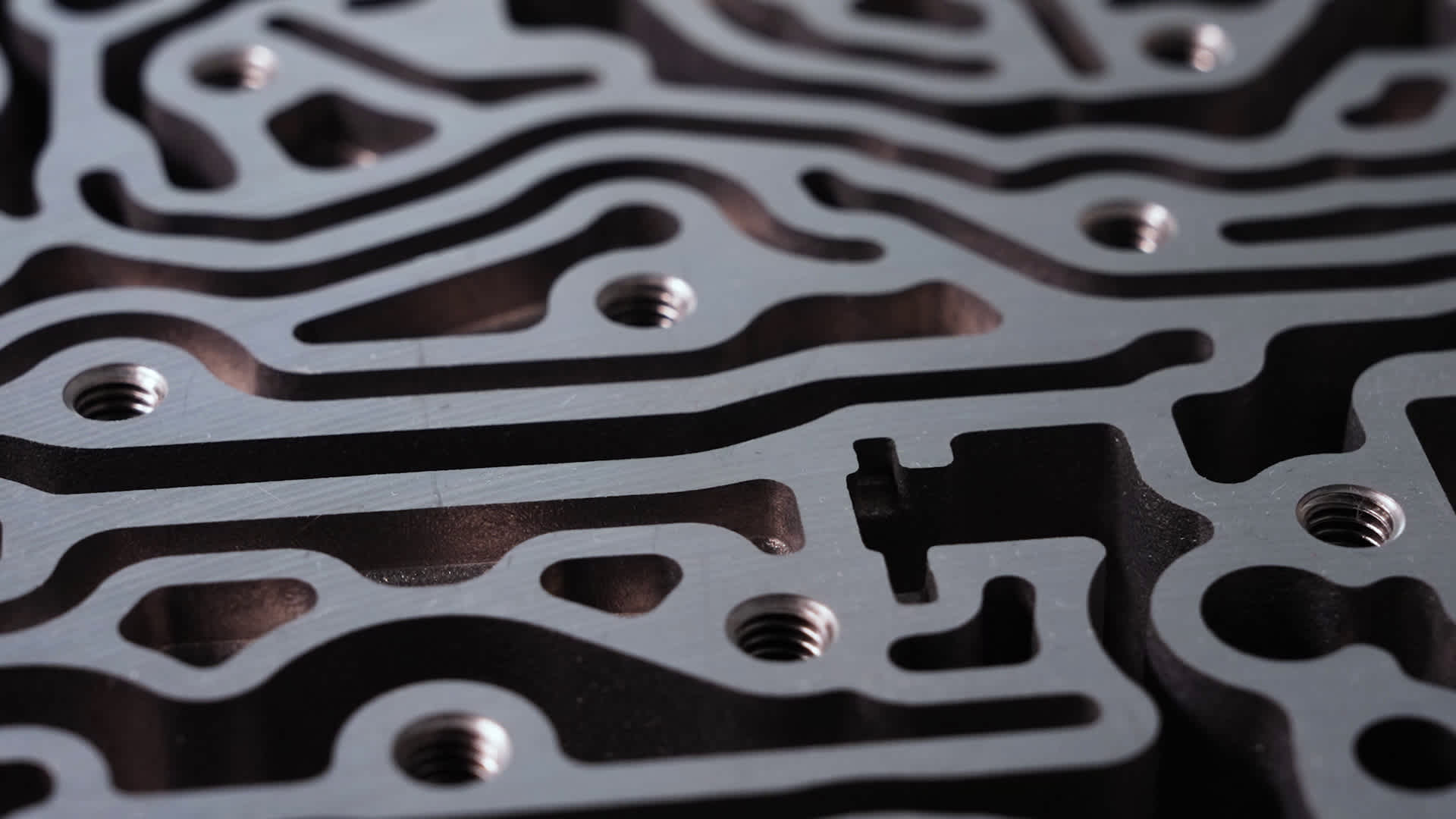

Robustness, power and reliability: these are the three essential qualities that Anger Machining - an Austrian company specialising in the production of machinery for the automotive industry - was seeking, with a view to equipping a new product line with the very best components in order to meet the changing needs of an industry that is constantly evolving. The compact and powerful HSD electrospindles were chosen by Anger to equip machining centres for aluminium machining operations for the traditional mobility industry, as well as for the hybrid and electric sector.

Founded in 1982 in Austria and acquired by the Taiwanese Tongtai Group in 2015, Anger Machining develops turnkey technology solutions for the machining of structural and high-precision components for the automotive industry, with high-profile names such as Stellantis, Daimler and Volkswagen among its customers. The Austrian company provides these leading groups with technologies that innovate machining processes as well as reducing production costs in a sustainable manner.

When Anger Machining was developing a new product line in 2017, there was a requirement for compact yet powerful electrospindles that could guarantee high levels of productivity, precision and flexibility: characteristics that are constantly in-demand within the unpredictable and rapidly-changing automotive market. Today, more than 100 HSD electrospindles equip Anger machining centres, the ES505 model in particular: this offers the perfect combination of power and reduced dimensions in order to guarantee precision when carrying out the work, as well as long-term reliability in today's increasingly challenging automotive industry.

When we designed a new product line in 2017, we were looking for a very compact yet powerful spindle. With HSD, we found the best solution. Within the last eight years we installed more than 100 HSD spindles in our machines.

Mathias Haingartner

R&D engineer